I-Semi-Auto Heat Transfer Screen Umugqa Wokuphrinta

UMSHINI WOKUphrinta isikrini

Isithasiselo

1. 1 Ibanga lesicelo:

Umshini we-ZSA-1B ulungele ukuphrinta iphepha, i-PCB, ipulasitiki, insimbi, ingilazi kanye nomkhiqizo owenziwe.

1.2.Izici:

1.2.1 Insimbi engagqwali itable yokusebenza, ukulungisa amayintshi ngaphambili nakwesokudla kwesokunxele, futhi icubungula ukuphrinta ngokushesha futhi kulula.

1.2.2 Izindlela zokulawula ezintathu zingakhethwa: okwenziwa ngesandla, okukodwa, okuzenzakalelayo

1.2.3 Ukuze kuhambisane Nokuhlukahluka kukayinki futhi uthole umphumela wokuphrinta ohlukile, ucezu lokubuyiselwa kwe-Scraper noyinki lungalawulwa ukuthi lume kwesokudla noma kwesokunxele.

1.2.4 Ukwamukela izakhi zikagesi ezinhle kakhulu ezenziwe abakhiqizi abadumile, izinjini ezivela kwamanye amazwe kanye ne-PLC.Umhlahlandlela womugqa wokunemba ophezulu ogayiwe uqinisekisa ukusebenza okushelelayo kanye nokuqina kwebhilidi yomshini.

2. Imininingwane

| 1 | Imodeli | I-XH-6090 |

| 2 | Indawo Yokuphrinta Enkulu | 600x900mm |

| 3 | I-Worktable Dimension | 700x1000mm |

| 4 | I-Max.Screen Frame | 1380x1100mm |

| 5 | Ubukhulu | 0-20mm |

| 6 | Isivinini esikhulu.Ukuphrinta | 13/min |

| 7 | Umfutho womoya | 3HP, 5.5-7.7kg/cm2 |

| 8 | Ukunikezwa kwamandla kagesi | 380V, 2KW |

| 8 | Usayizi Ophelele | 1600mm*1060mm*1680mm |

| 9 | Isisindo | 580 kg (cishe) |

| 10 | Umbala Wekesi | Okumhlophe/Kuluhlaza |

Singakwazi ukwenza abanye usayizi ngendlela oyifisayo kubasebenzisi.Usayizi owenziwe ngendlela oyifisayo nesisindo pls kunamathela kumkhiqizo wangempela esikhundleni salokho.

3. Izincazelo Zephaneli Yokusebenza

- Inkomba yamandla

- I-Barometer yokuphrinta i-squeegee

- Inkinobho yokulawula isivinini sokuphrinta

- Inkinobho yokulawula isivinini sokubuya kwamafutha

- Isibalo sokuphrinta

- Ukuphrinta kwesibili

- Imodi yokusebenza

- Isibonisi sesikhathi esizenzakalelayo

- Isikhathi esizenzakalelayo

- Enyuka ehla

- Ukubuya kwamafutha

- Ukuguqulwa kokuklwebha

- Imodi yokudonsa umoya

- Ukubuya kwamafutha asheshayo

- Ukuphrinta

- VULA/Vala Isithando somlilo

- I-Scraper Pressure

- I-valve yokuphepha

- Ikhanda lokuphrinta

4. Ukufakwa kanye Test

4.1 Umshini kufanele ufakwe endaweni ecacile, futhi izinga lokushisa ligcinwe ku-18-28 degrees.

4.2 I-fastener yokuhlola ingene kahle, futhi ingxenye ehambayo inamafutha okugcoba ngemva kokuvula ibhokisi lokhuni.Khetha indawo yokufaka umthombo womshini, faka irabha engu-4 emilenzeni, uyilungise futhi ugcine itafula lokusebenza livundlile.Intambo ephansi kufanele ixhunywe emshinini.

4.3 Intambo enemibala ephindwe kabili iyintambo ephansi, eminye intambo yomlilo.Ngemva kokuba izintambo sezixhunywe kahle.Cindezela okuthi 'Imodi Yokusebenza' ukuze 'Manuwali'.

Cindezela okuthi 'Imodi Yokudonsa Umoya' ukuze 'ukuncela njalo'.

Vula amandla (bona isithombe 1.4).Vula i-'Safety Valve'.

Lokho kuzokwenza ifeni isebenze.Beka i-lager surface paper etafuleni lokusebenza, uma iphepha belimuncwa itafula lokusebenza.Kusho ukuthi ukuxhumana kwezintambo kulungile.Uma iphepha lipheshulwe umoya, kusho ukuthi intambo yomlilo yamandla iphambene esigabeni, hlehlisa noma yiziphi izintambo ezimbili zomlilo.

4.4 Umfutho womoya womshini ngu-5.5~7KG/cm2.Uma umfutho womoya ungaphansi kwenombolo, khipha i-adjuster, jikela njengewashi, yenza umfutho womoya unyuke.Jikela ngokuphambene newashi kuzokwenza umfutho womoya wehle.

4.5 Cindezela u-'Operation Mode' ukuze ulawule 'mathupha'.Hlola umshini phezulu naphansi, ukunyakaza kwesokunxele nakwesokudla.

Cindezela inkinobho ethi 'Scraping conversion', hlola i-scraper, ne-oil return scraper.

Isexwayiso: Ayikwazanga ukwenza omunye umsebenzi, kuze kube yilapho konke okungaphezulu kusebenza kahle.Uma kungenjalo, izolimaza umshini.

4.6 Iqediwe ngenhla , ilandelela ukuhlolwa kokuphrinta okuzenzakalelayo nokukodwa.

4.6.1 Cindezela 'Imodi yokusebenza' ukuze 'Iyodwa', nyathela i-foot pedal, bese uqeda ukuphrinta kanye.

4.6.2 Cindezela 'Inkinobho Yokubuyisela Amafutha Asheshayo', Isibonisi sesikrini

Umnyakazo uthi:

Phansi - Ukunyakaza kwesobunxele - phezulu, Ukunyakaza kwesokudla kwe-Scraper

Ingakhuphula ukusebenza kahle kokuphrinta.

4.6.3 Cindezela 'Ukuphrinta kwesibili' VULIWE, umnyakazo uthi:

Down—Scraper Left movement — Right —- Left — Right — Up

Ifanele ukuphrinta kukayinki omkhulu.

4.6.4 Cindezela 'Imodi yokusebenza' ukuze Okuzenzakalelayo, lungisa Isilawuli Sesikhathi KT(0~10S).Umshini uqedele konke ukunyakaza okuzenzakalelayo.(Ifanele isisebenzi esinekhono, esikhundleni salokho i-Foot pedal)

4.6.5 Inkinobho Yezimo Eziphuthumayo

Inkinobho Yezimo Eziphuthumayo ingase iphakame lapho umshini usebenza.Kumelwe unyathele i-Pedal ye-Foot ukuze wenze umshini usebenze ngemva kokusebenzisa Inkinobho Yesimo Esiphuthumayo.

5. chaza umsebenzi

5.1.Faka futhi ulungise i-Net Frame

Jikela kokuthi 'Offer Air' (njengesithombe1.35), yenza i-Scraper phezulu, ukhulule isikulufu se-Net Frame Arm (njengesithombe1.9).Lungisa I-Net Frame Arm kuzo zombili izinhlangothi ukuze ibe ubude obufanele (njengesithombe2.25), faka i-Net Frame ku-clamp bese uqinisa isikulufu.(njengesithombe 1.29).Kuqediwe ukufakwa, qinisa isikulufu.(njengesithombe 1.9)

5.2.Lungisa usayizi wokuphrinta.

Shintshanisa irabha ye-scraper yokuphrinta ukuze ulungise ububanzi bokuphrinta ngokuvumelana nesicelo sakho.(njengesithombe 1.33).

Lungisa ubude bokuphrinta: Khulula izikulufu ezi-2 (njengesithombe1.11), lungisa kwesokunxele nesokudla endaweni efanele.Qinisa isikulufu.

Ukuphrinta kanye nesivinini sokubuya kwe-Oyili lungisa (njengesithombe3) 'Isivinini Sokuphrinta', kusivinini sakho esifanele.

5.3.Landela ukulandelana okungezansi ukuze ulungise i-scraper bese ubuyisela ummese wamafutha.

a.Ukuzungezisa: khulula izikulufu ezi-4 (njengesithombe1.24) ukuze ulungise ukuzungezisa.

b.Ukufana: lungisa izikulufu ezi-4 (njengesithombe1.12) ukuze ugcine isikrufu futhi ubuyisele ummese kawoyela uhambisana ne-Net Frame surface.

c.Isivinini: Lungisa isikulufu esingu-4 (njengesithombe1.12) ngakwesokudla ukuze ulawule isivinini sokuphakamisa se-Scraper nommese wokubuyisela uwoyela.Lungisa 'isivinini sokuphrinta' ukuze ulawule isivinini se-scraper.

d.Ukucindezela kwe-scraper: Lungisa i-valve yokucindezela (njengesithombe1.39) ukuze ulawule ukucindezela kwe-scraper (njengesithombe1.38).Funda inombolo evela ku-Barometer.

e.Donsela ifindo 'ikhanda lokuphrinta' ulikhiphe (njengesithombe 3.19), ukuze wehlise ummese wokubuyisela uwoyela wokukrwela nowokubuyisela.Kufakwe ummese wokubuyisela ukhuhla nowoyela cindezela 'ikhanda lokuphrinta'.

5.4.Lungisa ubude phakathi kwe-Net Frame ne-worktable.(Ngokuvumelana nobukhulu be-workpiece) Ngemuva komshini, vula umnyango.

Khulula isikulufu.(bona isithombe esingezansi) Jikisa Induku iye phezulu, jikisa Induku iye phansi.

Qinisa isikulufu.

| CHA. | Igama | CHA. | Igama |

| 1 | I-adaptha yokushintshwa kwe-pedal | 22 | Air Drum for scraper |

| 2 | Isondo eliphelele | 23 | Isikulufu se-Ink Knife Lock |

| 3 | Okokufaka kwamandla | 24 | Isilungisi se-Ink Knife Rotative |

| 4 | Ukushintsha Amandla | 25 | Ingalo ye-Net Frame |

| 5 | Isilungisi esincane se-Worktable | 26 | Insika ye-Lift Net Frame |

| 6 | I-Worktable Lock Screw | 27 | Isilungisi Esisheshayo seLift Net Frame |

| 7 | I-Net Frame Rotative Adjutor | 28 | Lift Net Frame Air Drum |

| 8 | I-Net Frame Height Adjusted Screw | 29 | Isikulufa ukuze Uqinise Uhlaka Lwenethiwekhi |

| 9 | I-Net Frame Isikulufu Esilungisiwe Kwesokunxele Nesokudla | 30 | Uhlaka Oluphelele Lwesokunxele Nesokudla |

| 10 | Imoto | 31 | Ithebula lomsebenzi |

| 11 | Ilokha yokunyakaza | 32 | Hook for Ink Knife |

| 12 | I-Scraper Speed Adjuster | 33 | I-Scraper |

| 13 | 34 | Ummese kayinki | |

| 14 | Air Drum for scraper | 35 | Air Drum for scraper |

| 15 | 36 | I-Emergency Stop | |

| 16 | Hudula iChain | 37 | Iphaneli |

| 17 | 38 | I-Scraper Barometer | |

| 18 | Umthunzi Wangaphandle | 39 | I-Scraper Pressure Adjustor |

| 19 | 40 | Umnyango Webhokisi Logesi | |

| 20 | I-Ink Return Knife Pressure Adjustor | 41 | I-Foot Pedal |

| 21 | I-Scraper Pressure Adjustor |

6. Isondlo:

6.1.Gwema uyinki kanye ne-organic solvent ukuvimbela imbobo yokumunca etafuleni lokusebenza.

6.2.Beka amafutha enjini amancane 10# phezu kwensika njalo ngesikhathi sokusebenza.

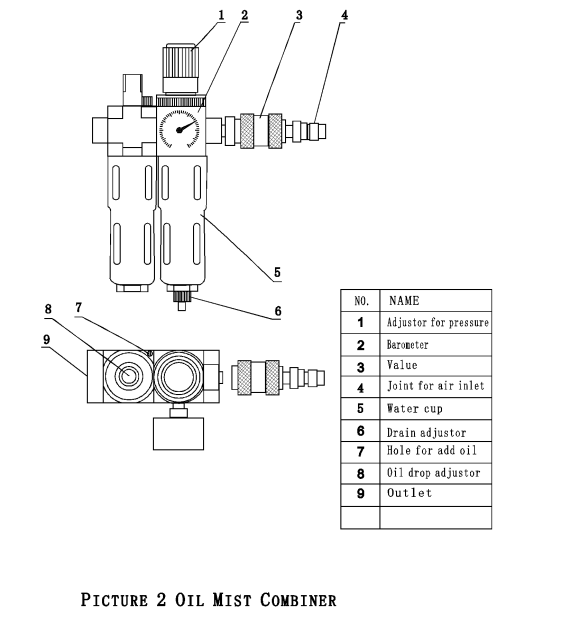

6.3.Umshini unomshini wokuhlanganisa i-Oil mist (bheka isithombe 2).

6.4.Hlanza Isihlungi (njengesithombe2.7).Nikeza umoya, vula inkinobho yokukhipha amanzi (njengesithombe2.8).

Geza isipontshi enkomishini yamanzi (njengesithombe2.7) imvamisa.Susa Isihlungi, khipha isipontshi, usishiye imizuzu embalwa emanzini ahlanzekile, bese usomisa.

7. Okunamathiselwe

1. Imanuwali yokusebenza

2. I-Screwdriver 2 pcs, i-Spanner engu-10, i-hex Spanner, i-Rob

3. 4 Unyawo lwerabha

4. Ummese we-Scraper no-Ink ubuyisela 350, 400

************************************************** ************************************************** ************************************************** ******************

UMSHINI WE-POWDER COATING

Incazelo emfushane

Ngemva kokunyathelisa okokusebenza okuhambisanayo esikhundleni somsebenzi wezandla ovamile.Lo mshini ulungele ukusetshenziswa, usebenza kahle kakhulu, uvumelana nezimo, futhi awunakho ukungcola, okwandisa kokubili ukukhiqiza nokusetshenziswa kwezinto ezingavuthiwe, kanye nokukhiqiza izithombe ezinhle.

Kulo mshini, izingxenye zesikhundla esiyinhloko ezifana nokumunca impushana, i-transducer zingeniswa kwamanye amazwe ngezinzuzo zokuqina nokuzinzile.Ikakhulukazi, lo mshini usebenza kahle nalabo abanesidingo esikhulu sephepha, ifilimu, i-glitter, nempushana encibilikayo eshisayo.Wonke amadrayivu kulo mshini awashintshile isivinini.Uma kudingekile, ingaphinda ixhumeke nezinto zokusebenza okomisa kanye nemishini ye-UV yokwelapha isithombe.

Amapharamitha Abalulekile Wezobuchwepheshe:

| Imodeli | Amandla Aphelele | Ububanzi Bebhande Lokudlulisela | Ububanzi bePowdering | Ukujiya Kwephepha | Ubukhulu Sebonke | Isivinini (Ama-PC/Ihora) |

| I-ZSCT-II | 4.5KW | 1000(mm) | 900(mm) | 1—5(mm) | 2000*1700*2000 | 2000 |

Funda imanuwali ngokucophelela, ngaphambi kokusebenzisa umshini.Ungalungisi noma iyiphi inkinobho ngaphambi kokuxhuma emandleni kagesi.

Imanuwali Yokusebenza

Isikhumbuzo esifudumele: Impushana ngeke ihlakazeke kuze kudlule ifilimuinzwa.

Lo mshini ufakwe amaswishi ahlukanisiwe akho kokubili ukumunca amandla ukuya phezulu naphansi, kanye namaswishi okulethwa, uthuli, ukuphakela impushana, kanye ne-electrostatic neutralizer.

Inqubo yokuqala

- Vula amandla amakhulu kukesi elingakwesobunxele.

- Vula inkinobho yamandla (Bheka isithombe II-2).

- Vula injini yokumunca amandla ephezulu (Bheka isithombe II-8), bese uthethelela imvamisa ye-transducer ibe ngu-38-42HZ.

- Vula injini emunca amandla eyehlayo (Bheka isithombe II-11), futhi ulungise imvamisa ye-transducer ibe ngu-55-65HZ.

- Vula amandla okulethwa(Bheka isithombe II-4), bese ulungisa ukushintshela ku-20-65HZ.

- Vula isilungisi sokuphakela impushana (Bheka isithombe II-15), bese ulungisa ukushintshela ku-20-65HZ.

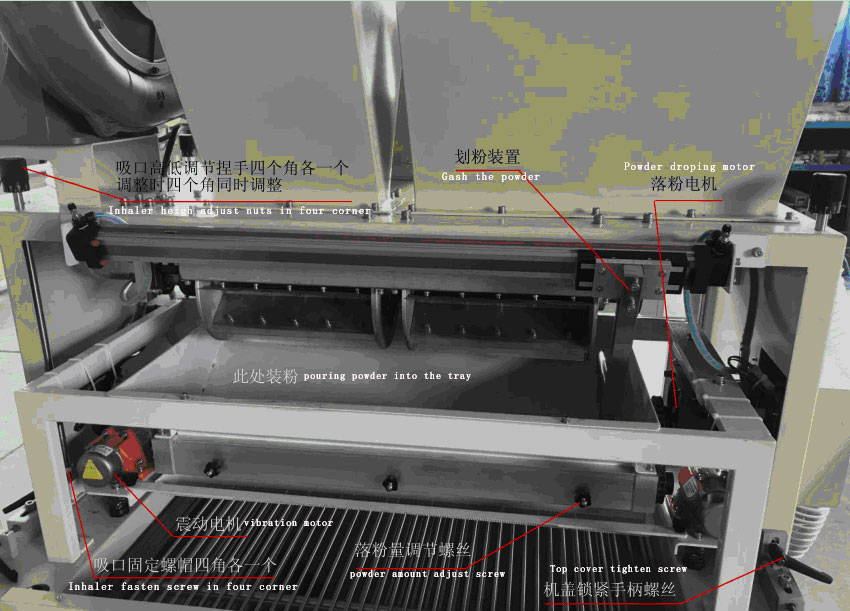

- Thela impushana encibilika eshisayo ethreyini yothuli, bese uvula injini yothuli (Bheka isithombe II-17).Okokuqala, ukulungisa isivinini sothuli (ngokushesha, i-powder eyengeziwe).Noma ukulungisa amantongomane amathathu ngaphansi kwefaneli yokuthela uthuli (Bheka isithombe I-4) ukuze kuthethelelwe inani lempushana, ukuze kuhlangatshezwane nemfuneko yomkhiqizo yokujiya kwempushana nokulingana.

- Umqoqi wempushana kukesi elingakwesobunxele (Bheka isithombe II-21) unomsebenzi wokuphromotha i-powder-cycling.Imvamisa, ishintsha ibanga ukusuka ku-60 kuye ku-70.

- Vula inkinobho ye-electrostatic neutralizer (Bheka isithombe II-13)

Lungisa umshini

1.Ukulungisa isikhala phakathi kokumunca impushana iye phezulu naphansi ibe ngu-2-3mm.

Uma kusekhona isondo legiya kwisampula ngenkathi isebenza (imvamisa, selivele lilungisiwe ngaphambi kokukhishwa), ungakwazi ukulungisa kahle ubude ukuze udonse amandla phezulu ukuze uhlangabezane nezidingo zomkhiqizo.

1.1 Khipha amantongomane amane ekhoneni.Isikhumbuzi: Lungisa ubude kuphela ngemva kokukhulula amantongomane amane.(Bheka isithombe)

1.2 Khipha inadi (Bheka isithombe 1), lungisa kahle ukuphakama ukuze uthole amandla akhuphukela phezulu (Bheka 1, 21, 22).Noma (Bheka isithombe 1) Jikela ngokwewashi igebe lisondele.Jikela ngokuphambene newashi igebe libe banzi.

1.3 Phendula kahle amantongomane amane endaweni yokumunca impushana, yenze ilingane.(Bheka isithombe 1) Qinisa izikulufu ezimnyama (Bheka isithombe 1)

Inqubo yokugaywa kabusha kwempushana

1.Uma kunezinsalela zempushana emkhiqizweni, kungcono ukwenyusa ijubane lempushana emunca injini ikhuphukele (Bheka isithombe Ⅱ-8).Kodwa-ke, ukugeleza komoya okuphezulu nakho kungabangela ukugxuma kwephepha, lungisa kahle.

Uma kusekhona izinsalela zempushana emkhiqizweni, emva kokwenyusa ijubane lokumunca impushana iye phezulu, hlola ukuphakama kokuya phezulu naphansi.Uma igebe libanzi kakhulu, landela isinyathelo sangaphambilini ukuze ulungise ukuphakama.

Hlola isikhwama sothuli esingenayo impushana ukuvimba imbobo yomoya.Ngokusho kobukhulu be-powder, kuyadingeka ukuhlanza isikhwama sothuli ukuze ugweme ukuvimba umgodi womoya.

Hlola uhlangothi olungezansi lomshini, qiniseka ukuthi uhlelo lokusiza lokugaywa kabusha kwempushana luvuliwe.

Ukulawulwa kwenani le-shaking powder

- Lungisa isilawuli sesivinini sokunyakaziswa kwempushana (Bheka isithombe II-22).

2. Lungisa isilawuli sejubane le-powder shake (Bheka isithombe II-22) namanje esingakafinyeleli isidingo sakho.Ingakwazi ukulungisa isikulufu kwesokunxele sekheji(Bheka isithombe).

Inqubo yokucisha amandla

- cisha isilawuli sethreyi yothuli (bheka isithombe II -17)

- Vala isilawuli sokuzamazama (bona isithombe Ⅱ-22)

- vala inkinobho yokuncela amandla ukuya phezulu (bheka isithombe II-7)

- vala inkinobho yokuncela amandla ukuya phansi (bheka isithombe II-10)

- vala inkinobho yokuletha (bona isithombe II-4)

- ukushintsha kwe-switch (bheka isithombe II-21)

- ukushintsha kwesilawuli sokuletha impushana (bona isithombe Ⅱ-15)

- vala inkinobho yamandla amakhulu (bona isithombe II-2)

- Hlanza iphaneli yokulawula bese uyimboza ngejazi lothuli

Ukuba khona komshini

1. Ngemva kokusebenza isikhathi esithile, vula i-baffle, bese ugcwalisa lezo zingxenye ezisebenzayo ngamafutha enjini angu-20#.Uma iketango lixega, sebenzisa igiya elinwebekayo ukuze ulungise.

2. Ngenkathi ushintsha izinto ezingavuthiwe ezifana ne-glitter ne-hot melting powder, sebenzisa umoya ocindezelwe ukuze uhlanze zonke lezi zingxenye ukuze ugweme ukuxutshwa kwempushana.

3. Ngokusho kobukhulu be-powder, kuyadingeka ukuhlanza isikhwama sothuli ukuze ugweme ukuvimba umgodi womoya.

Ukusebenza umshini ongenalutho

Vula inkinobho yokukhuphuka komshini (Bheka isithombe 3).Vula iswishi engxenyeni engaphezulu yengxenye yomshini izophakama, kungenjalo yehle.

Guqula iswishi yokulethwa ibe-othomathikhi (Bheka isithombe II-4), bese uvala wonke amanye amaswishi, wenze ifilimu yokushisisa kwangaphambili idlule.

Ukulungiswa Kwephutha

1. Sicela ufake i-speed governor ngenkathi ingasebenzi.

2. Sicela ulandele imiyalelo yokuba khona komshini uma impushana ingamuncwa ngokuphelele njengakuqala.Noma ungakwazi futhi ukwandisa i-destaticizer ukuze ubhekane nale nkinga.

3. Sicela uhlole impushana ukuthi ihlanzekile futhi yomile yini uma uthuli lunzima.Uma impushana imanzi, sicela uyivale ngaphansi kwelanga.

4.Uma i-powder recycling tube block, Sicela uhlole phansi kohlaka vula isistimu yomsizi wezinsalela.Noma Hlola impushana imunca iye phansi, qinisekisa ukuthi iyasebenza.

5.Vula iswishi engxenyeni ephezulu yomshini izophakama.

************************************************** ************************************************** ************************************************** ******************

I-Manipulator